language

04

Jun 25

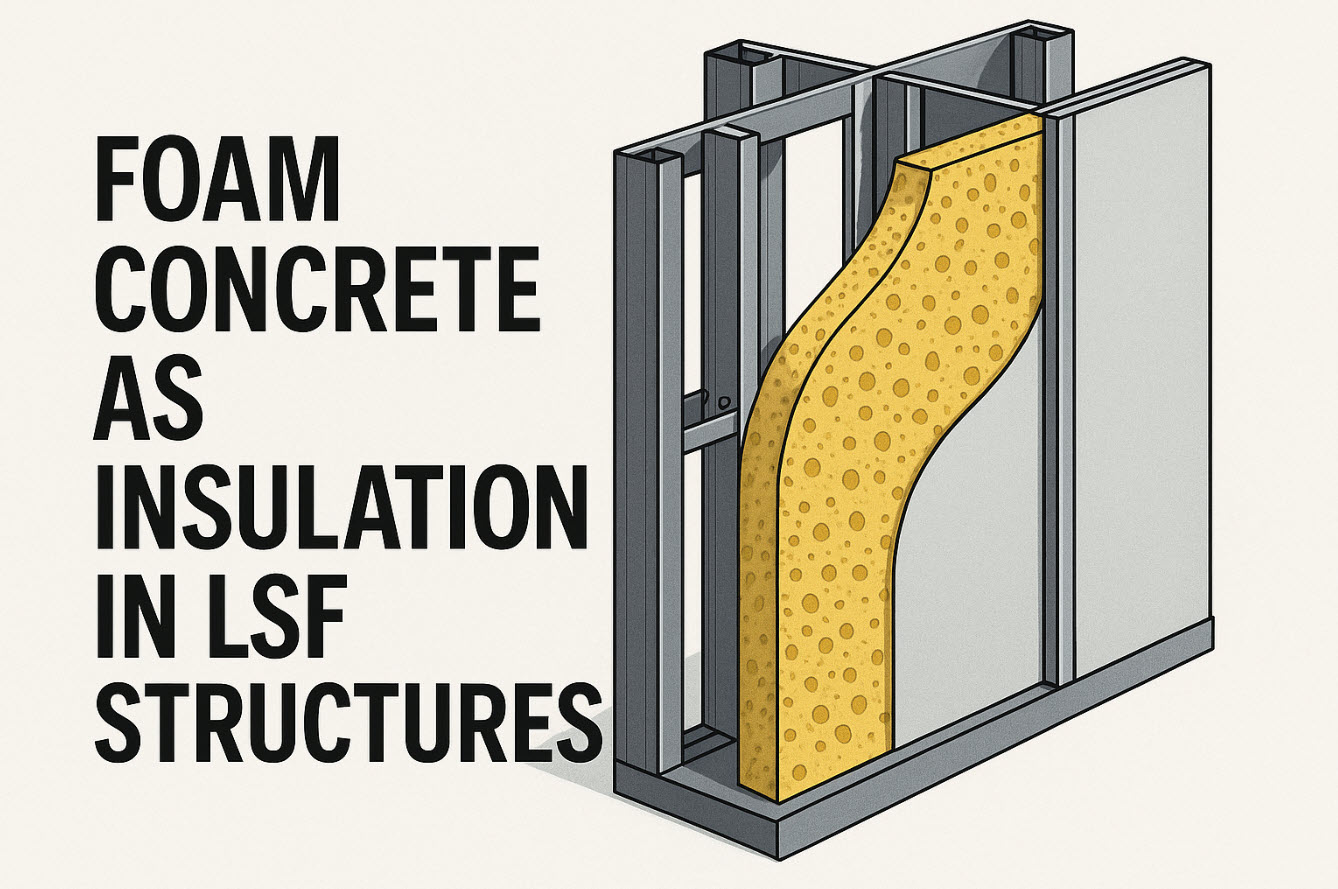

Using Foam Concrete as Insulation in Light Steel Framing Structures

Great. I’ll begin a deep technical research article on the use of foam concrete as insulation in Light Steel Frame (LSF) structures, covering its thermal, acoustic, and fire resistance properties.

I’ll also explore current engineering practices, benefits, challenges, and performance metrics—drawing from international standards and technical literature where available.

I’ll let you know once the article is ready for your review.

Introduction to Light Steel Frame (LSF) Systems

Light Steel Frame (LSF) construction uses thin, cold?formed steel sections (studs and tracks) as the primary structural frame for walls and roofs. LSF walls may be loadbearing or non?loadbearing (partitions), and steel is often used in combination with other structural elements. Steel framing is very strong in tension and compression and has a high strength?to?weight ratio; a typical LSF building is comparable in cost to a timber?frame building. Because steel elements are prefabricated and light, LSF structures can be assembled rapidly with high precision (often under factory conditions) and with minimal onsite waste. Other attributes of LSF include long service life (durable if kept dry), non?combustibility (steel does not burn, though it softens at high temperature), good seismic performance (ductility), and resistance to termites and vermin. (Steel does conduct heat, so design must incorporate thermal breaks/insulation to prevent bridging.) Overall, LSF offers energy?efficient construction: extremely low U?values can be achieved by sandwiching thick insulation layers between the steel studs, which minimizes thermal bridges and creates a highly airtight enclosure. Modern LSF codes (e.g. AISI S100 in North America, Eurocode 3 Part 1-3 in Europe) and performance standards guide design of cold?formed steel walls for structural and fire safety, ensuring that these steel?framed systems meet international building requirements.

Foam Concrete: Composition, Properties, and Types

Foam concrete (also called foamed or cellular concrete, or aircrete) is a cementitious material made by mixing a cementitious slurry (often cement + water, sometimes with fly ash or other binder) with a preformed foam to entrain a high volume of air bubbles. It contains little or no coarse aggregate: instead, lightweight fine aggregate (or none) and foam generate up to 90% porosity by volume. Typical densities range from about 400–1600?kg/m³ (dry) depending on the foam content. This extreme cellularity gives foam concrete very low self-weight (often 20–80% lighter than normal concrete) and high flowability – it can be poured or pumped into forms without vibration or compaction. The foam (often a stable synthetic or protein?based surfactant) creates uniform bubbles ~0.1–1?mm in size. By adjusting the mix and foam dosage, foam concrete can be produced in various grades: very low?density mixes (200–600?kg/m³) for insulating fills, medium?density (600–900?kg/m³) for blockwork or panels, and higher?density (~1000–1600?kg/m³) for semi-structural applications. Some formulations use additives (fly ash, microspheres, polymers, fibers) to tailor properties; for example geopolymer or magnesium phosphate cement binders can yield higher strength or heat resistance. In practice, foam concrete is widely used in modern construction worldwide (e.g. Turkey, Germany, UK, Thailand) for insulated wall panels, blocks, floor and roof insulation, and filling voids.

Foam Concrete as Insulation: Technical Performance

Thermal Insulation

Foam concrete’s high porosity makes it a good thermal insulator compared to normal concrete. Its thermal conductivity k decreases strongly with density. For example, Zhang et al. found that when foam concrete density varied from 585 to 1370?kg/m³, k increased from about 0.15 to 0.48?W/m·K. In practical terms, low-density mixes (400–600?kg/m³) typically have k on the order of 0.1–0.2?W/m·K, while denser mixes approach 0.4–0.5?W/m·K. Thus, foam concrete provides moderate insulation – better than ordinary dense concrete (?1.4?W/m·K) but much less than lightweight synthetic foams (EPS ~0.03–0.04?W/m·K) or mineral wool (~0.035?W/m·K). The actual k depends on cement type and foaming gas: e.g. foam created with CO? has lower k than with air or hydrogen. In any case, higher foam volume (lower density) yields more porosity and hence lower conductivity. In design, the reduced conductivity of foam concrete must still be accounted for: roughly 200–300?mm thickness of foam concrete may be needed to match the R-value of only ~50?mm of polystyrene, for example. That said, foam concrete can be poured to completely fill cavities, eliminating voids and reducing thermal bridging around studs. In LSF walls, concrete?filled cavities can thus significantly slow heat flow through the section.

Acoustic Insulation

The open-cell structure also gives foam concrete sound-absorbing properties. Studies report that cellular (foamed) concrete has much higher acoustic absorption than dense concrete. For instance, foamed walls have been measured to absorb sound about ten times more effectively than a solid concrete wall. Thin samples of glass-fiber?reinforced foam concrete (GFC) showed remarkably high absorption (α≈0.7–1.0) even in low-frequency bands (40–150?Hz). In one study, alkali-activated slag foam concrete with 25–35% foam content achieved peak absorption coefficients of 0.8–1.0 in the mid–high frequency range (up to 2000?Hz). In general, acoustic performance improves as density decreases (more porosity). While few precise standards exist for foam concrete’s sound transmission (most data are experimental), these findings indicate foam concrete can attenuate noise substantially. In LSF buildings, a foam?filled wall will typically outperform an unfilled or fully solid wall in sound insulation, though dense fiber insulations (mineral wool) might give equal or better performance per unit thickness. Overall, foam concrete can function as both thermal and acoustic insulation in one material.

Fire Resistance

Foam concrete is inherently fire-resistant because it is cementitious and contains no organic binder. The cement matrix is noncombustible, and the moisture in the pores can absorb heat as vaporizing water, improving fire endurance. Indeed, foam concrete has been used to enhance fire ratings of steel?framed walls. Recent fire tests (both numerical and experimental) on LSF walls filled with lightweight concrete show significant fire protection benefits. For example, Upasiri et al. (2022) numerically compared LSF panels with various cavity fillings (Autoclaved Aerated Concrete (AAC) 600?kg/m³, foam concrete (FC) 650?kg/m³, and FC 1000?kg/m³) to empty or mineral wool?insulated cavities. All concrete?filled panels showed higher fire?resistance (R?values) than unfilled panels, with the 1000?kg/m³ foam concrete mix giving the best performance. In other words, higher-density foam concrete (and AAC) imparted greater insulation and structural support in fire. (Note that while steel itself weakens at ~300–500?°C, the insulation provided by plasterboard and infill delays steel heating.) Thus foam concrete as cavity infill can roughly double the time to structural failure in standard fire tests compared to empty walls. International tests like ISO?834 and ASTM?E119 would similarly classify foam?concrete?filled LSF walls as fire?rated assemblies, provided sufficient thickness and board linings are used. Additionally, foam concrete’s lack of organics means it produces no toxic fumes in fire. In summary, foam concrete dramatically improves LSF wall fire resistance while being itself noncombustible.

Advantages of Foam Concrete in LSF Buildings

Using foam concrete as insulation in LSF frames offers several benefits:

-

Energy Efficiency: Foam concrete adds thermal mass to the wall, smoothing indoor temperature swings. Its low conductivity improves wall R-value compared to empty cavities. Because it can fill the entire cavity, it eliminates small gaps and thermal bridges around studs.

-

Structural Support: Higher-density foam mixes can carry some in-plane loads, bracing the steel framing. This can stiffen panels and reduce stud buckling. (In practice, however, LSF design typically counts on the steel for all gravity/shear loads, with the infill acting as non-structural insulation.)

-

Fire Safety: As noted, foam concrete is noncombustible and can enhance the fire rating of LSF partitions and claddings. Unlike organic foams (EPS, PUR), no flame-retardant additives are needed.

-

Acoustic Damping: The air-entrained matrix absorbs sound, improving room-to-room noise isolation without separate absorptive layers. Combined with rigid linings, foam concrete can raise the STC (Sound Transmission Class) of a wall.

-

Durability & Moisture: Cement-based foam concrete does not sag, settle, or off-gas over time. It resists mold and rot (no organic binder) and can be formulated to be water-resistant. One industry report notes foam concrete insulation has a much longer useful life (?100?years) than fibrous insulations (~25?years) because it does not shrink or degrade.

-

Ease of Installation: Foam concrete can be injected or poured on-site as a liquid (then hardens), automatically filling voids. Unlike cutting and fitting batts, foam is monolithic and requires no battens or sealants. This can simplify construction and eliminate labor errors (gaps or compression of insulation). Specialized pump systems can deliver foam concrete into prefabricated LSF panels or in-place framing.

-

Resource Use: Foam concrete can incorporate industrial byproducts (fly ash, slag) as cement replacement, lowering embodied CO?. Because it replaces heavier materials, it can reduce overall material weight and waste. LSF with foam infill typically uses fewer total materials (by weight) than masonry or thick timber walls, with high recycled steel content already built in.

In practice, these advantages mean LSF walls insulated with foam concrete can achieve very high thermal and acoustic performance in a single step, without needing separate insulation layers, while also improving durability and fire safety. For example, one modular building system explicitly marries foam concrete with LSF to get “exceptional… thermal and sound insulation” in its wall panels.

Challenges and Limitations

Despite its benefits, foam concrete use in LSF also poses challenges:

-

Shrinkage and Cracking: Cellular concretes typically exhibit higher drying shrinkage than normal concrete. Studies report 0.1–0.35% volume shrinkage in hardened foam concrete. Uneven curing can cause cracking, especially near exposed surfaces. Mitigation (e.g. adding fibers, shrinkage-reducing admixtures, or slower curing) is often required. Cracking can create thermal gaps or allow moisture ingress, undermining insulation.

-

Low Strength: Foam concretes have low compressive strength (often only a few MPa at low densities). This limits their ability to carry loads. In LSF applications, one must ensure the concrete infill does not impose excessive lateral pressure on the studs (i.e. formwork must contain the slurry until it sets). Typically foam concrete is used as a non-structural fill, and the steel frame is engineered for the full load.

-

Moisture and Corrosion: Fresh foam concrete has high water content. If not properly cured or protected, residual moisture could corrode the steel studs or coatings. Proper waterproofing of the cavity (e.g. with vapour barriers) and use of galvanised/stainless steel profiles are needed.

-

Weight and Handling: Although light by concrete standards, foam concrete is heavier than fibrous insulations. For deep cavities, the additional dead load on the frame may require stronger sections or bracing. Transport and pumping of the mix can be logistically more complex than bringing in rolls of insulation.

-

Quality Control: Producing uniform foam concrete requires controlled mixing (foam quality, water content, binder). Variations can lead to uneven insulation or densities. Consistency and curing conditions must be monitored on site or in a factory setting.

-

Construction Integration: Unlike pre-cut insulation boards, foam concrete typically must be cast in place. This requires formwork or rigid backing sheets during pour, and enough time for curing before finishing. In retrofit or phased construction, injecting foam into enclosed cavities can be difficult. Panelized systems (precast foam-concrete panels) avoid this, but require factory production.

Overall, these limitations mean that use of foam concrete in LSF demands careful engineering: designs must account for its moisture and shrinkage behavior, and on?site application must follow strict procedures. Building codes may not explicitly cover foam concrete inserts in steel walls, so test verification (e.g. fire or load tests) is often needed to certify performance of each assembly.

Engineering Integration Techniques

In practice, foam concrete is integrated into LSF buildings in two main ways: in?place filling and prefabricated panels.

-

In-Situ Filling: The steel frame is erected with temporary sheathing or formwork on one or both sides. The foam concrete slurry is then pumped into the cavity, filling the space between studs. Care is taken to pour gradually and evenly to avoid undue lateral pressure. After pouring, the material is leveled flush with edges. Once cured, outer finishes (e.g. plasterboard, cladding) are applied. This method creates a monolithic, gap-free insulation layer. (Indesol’s system, for example, relies on pouring foam concrete into steel-framed modules to achieve a seamless fill.)

-

Prefabricated Panels or Blocks: Foam concrete can be cast into modular wall panels with steel skins, or made into blocks that fit between studs. For instance, autoclaved aerated concrete (AAC) or foam concrete blocks can be dry-stack inside a light steel frame, then anchored and sealed. Sandwich panels with foam concrete core and thin steel or board facings are also possible. These approaches allow factory quality control of the concrete mix and dimensions. The panels are then mounted on the LSF framing like cladding.

In both cases, key practices include: ensuring vapour control (foam concrete can exude moisture during curing), verifying fill density (using test samples), and coordinating foam curing time with construction schedule. Fast-curing cement formulations or additives can accelerate setting. Engineers also sometimes pre-coat studs with corrosion-resistant primer or wrap them to prevent alkaline attack. When properly executed, foam concrete can be combined with LSF just like any other cavity insulation, but it yields a truly monolithic wall core rather than a fluffy filler.

Comparison with Other Insulation Materials

Foam concrete is one of many insulation options for LSF walls. Its trade-offs relative to common materials include:

-

Mineral Wool (Rock Wool/Glass Wool): Thermal conductivity is similar (~0.032–0.040?W/m·K), so both require similar thickness for given R-value. However, mineral wool is fibrous (needs bats/blankets and careful fitting) while foam concrete is cast-in-place. Mineral wool is completely noncombustible; foam concrete is likewise fireproof. Foam concrete provides better sound absorption (due to continuous mass) whereas fibrous wool mainly attenuates airborne sound. Over time, wool can settle or draw moisture; foam concrete is dimensionally stable.

-

Expanded/Extruded Polystyrene (EPS/XPS) or Polyurethane (PIR/PUR): These organic foams have much lower conductivity (~0.025–0.04?W/m·K), so they achieve the same insulation in thinner layers. They are lighter and easy to cut. However, they burn readily and typically require fire barriers (like gypsum boards) in walls. Foam concrete is heavier and bulkier for equivalent R, but inherently fire?safe. Also, EPS and PIR are petroleum?based and not recyclable (foam concrete can include recycled ash/slag).

-

Vacuum Insulation Panels (VIPs) or Aerogels: These advanced materials have ultra?low conductivities (VIP ~0.005?W/m·K, aerogel ~0.015), far outperforming foam concrete. They can yield very thin assemblies. However, VIPs are extremely fragile and expensive, and aerogels are costly. Neither is easily cast in place, so in practical LSF walls these are usually separate inserts, not continuous fills.

-

Concrete or Cement Board: Dense concrete has high k (1.4), so poor thermal insulation. Autoclaved Aerated Concrete (AAC) is a precast foam?concrete block (k0.12–0.14), roughly similar to low-density foamed mixes; it is often used in panels or blocks for LSF walls. AAC is stronger (due to autoclaving) but more expensive.

In summary, foam concrete sits between fibrous and polymeric insulations: it is mineral/noncombustible like wool but has higher conductivity (requiring more thickness). Its unique advantage is that it simultaneously forms structure and insulation. Foam concrete can also support some stiffness (unlike loose fill) and bond to the steel frame. Engineering criteria thus choose it when fire/sound performance, monolithic fill, and durability are prioritized over minimum thickness or absolute R-value.

Case Studies and Applications

Foam concrete has seen real-world use in various LSF and modular systems. For instance, Indesol (a modular building manufacturer) uses a patented process where foam concrete is combined with a light steel frame to create highly insulated wall modules. They claim this “innovative material” grants exceptional thermal and acoustic insulation in their prefabricated buildings. In another example, a 2022 Northumbria University study modelled LSF walls filled with foam concrete and found that panels with 1000?kg/m³ foam concrete passed ISO 834 fire tests with the longest fire-resistance ratings.

Historically, foam concrete’s insulating potential was recognized long ago. For example, in the 1930s a British railway bridge (Smithy Bridge) was infilled with foamed concrete to lighten loads. More recently, US highway engineers have used foam concrete as a lightweight fill (e.g. raising a road culvert base) to avoid overloading existing structures. In building construction, non-autoclaved foam concrete blocks and panels have been used in Europe and Asia for energy-efficient walls and floors. (Anecdotally, several UK and Philippine projects in the 2010s experimented with foam?concrete cavity fill in steel-frame houses.)

Where published case studies are available, they consistently report that foam?filled LSF walls meet or exceed performance of comparable timber-frame or unfilled walls. For example, fire tests of plasterboard-lined LSF walls have shown that adding foam concrete infill can double the fire-resistance time compared to insulation-free cavities. Energy modeling suggests that replacing a traditional loose-fill insulation with a thin layer of foam concrete can reduce heat loss and improve thermal comfort (albeit with thicker walls).

In sum, while not yet mainstream in every market, foam concrete is a proven option in specialized LSF and modular systems around the world. Its successful use in high-performance demo buildings (university research houses, net-zero modular homes) and in industrial/regional projects confirms its viability as an insulator.

Summary and Future Outlook

Foam concrete offers a versatile insulation solution for light steel framing: it combines the low thermal conductivity of a cementitious matrix with the air porosity of foam to yield good energy efficiency, sound damping, and fire safety in one material. Technically, foam concrete stands out for its monolithic fill – by casting a foam?cement slurry into LSF cavities, builders create seamless, void?free insulation without mechanical fixings or membranes. The material’s drawbacks (shrinkage, moisture content, limited strength) can be managed by proper mix design and construction technique. Compared to conventional insulators (mineral wool, EPS, etc.), foam concrete offers a unique mix of noncombustibility and robustness, at the cost of requiring thicker layers.

Looking ahead (2025+), we expect further refinements in this technology. Ongoing research aims to reduce foam concrete density and shrinkage while boosting strength – for example using advanced polymers or nanomaterials as additives. Coupling foam concrete with phase-change materials (PCM) or aerogel composites is being explored to enhance thermal storage and insulation without bulk. On the systems side, automated spraying or 3D?printing of foam concrete into cold?formed steel molds could speed up modular fabrication. Foam concrete’s sustainability may also improve: more replacements of Portland cement (fly ash, gypsum, geopolymer binders) are being tested to lower carbon footprint.

In terms of standards, we may see future inclusion of “cellular concrete infill” in cold-formed steel wall tables (analogous to fiber insulation values) and possibly new test protocols for these hybrid walls. As energy codes become stricter, the demand for high?performance wall systems could make foam?infused LSF walls more attractive. In sum, foam concrete as LSF insulation is a niche but growing practice; its continued development promises to give designers a robust mineral?based insulator that meets the high thermal, acoustic, and fire safety demands of modern construction.

Sources: Recent research (2020–2025) on foam concrete properties and LSF wall performance, industry reports, and international building guidelines were reviewed to compile this analysis. Relevant standards (e.g. Eurocode 3, AISI S100 for cold-formed steel; ASTM fire tests) provide the design framework for LSF/foam?concrete systems. All technical claims are supported by the cited literature and technical sources.

03

Jun 25

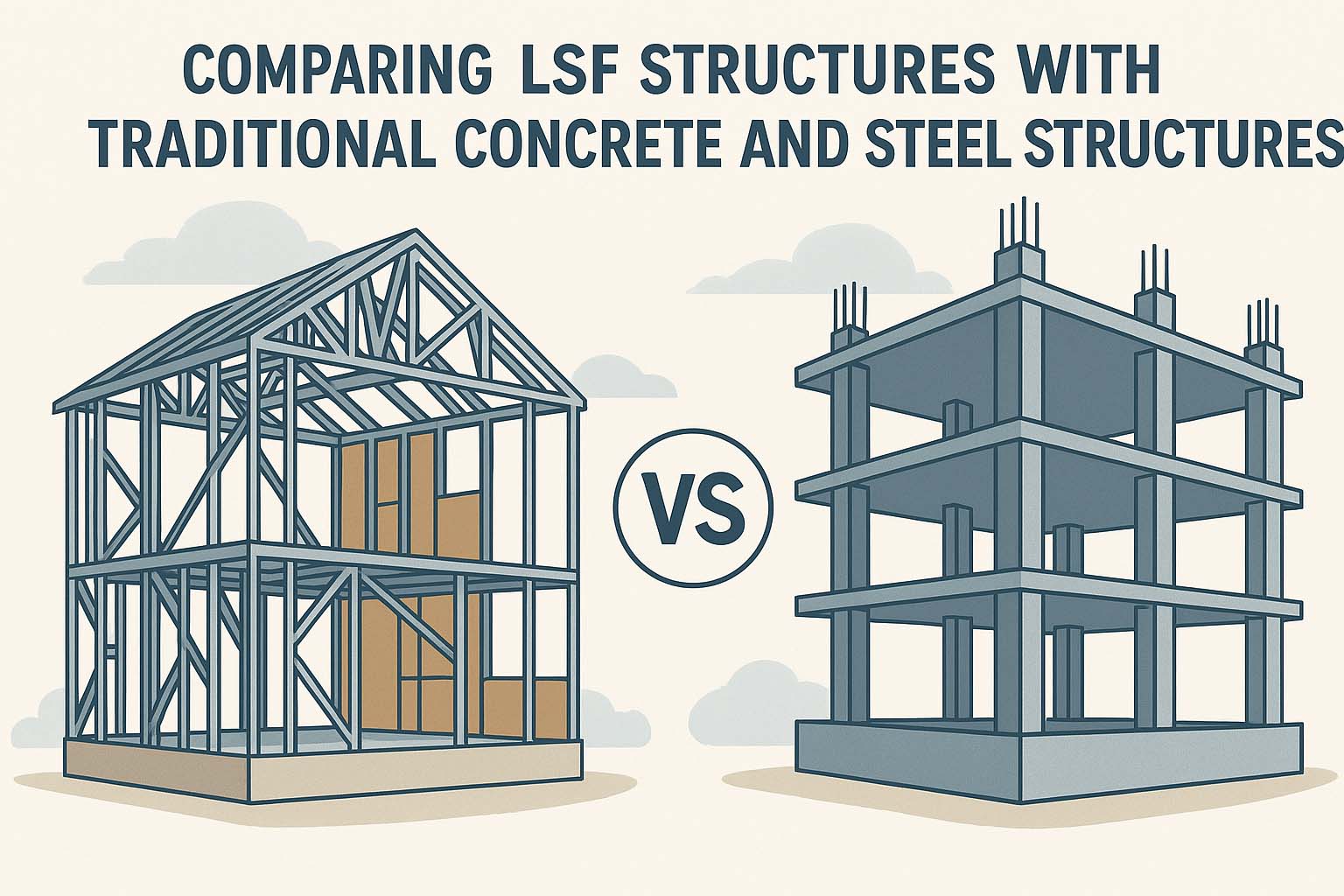

Comparing LSF Structures with Traditional Concrete and Steel Structures

In recent years, LSF (Light Steel Frame) structures have gained significant popularity as a modern alternative to traditional construction methods using concrete or hot-rolled steel. With increasing demands for faster, more efficient, and sustainable building solutions, LSF systems offer distinct advantages. Below, we compare LSF with conventional concrete and steel structures across several key aspects:

1. Weight and Material Efficiency

One of the most noticeable differences is weight. LSF structures are significantly lighter than both concrete and hot-rolled steel buildings. This lightweight characteristic reduces foundation loads, leading to cost savings in foundation design and making LSF ideal for areas with weak soil or retrofit projects where additional load capacity is limited.

2. Speed of Construction

LSF systems are prefabricated and delivered ready to assemble, allowing for extremely fast on-site installation. While concrete requires time for curing and hot-rolled steel demands complex welding and bolting, LSF structures can be assembled in a matter of days or weeks, significantly reducing project timelines.

3. Seismic Performance

Thanks to their light weight and ductility, LSF structures perform exceptionally well in seismic zones. The reduced mass minimizes inertial forces during an earthquake, and the steel frame provides a flexible yet strong skeleton that can absorb and dissipate seismic energy more effectively than rigid concrete structures.

4. Accuracy and Quality Control

LSF components are typically produced using CNC-controlled roll-forming machines, resulting in high dimensional accuracy. Unlike concrete which is subject to site variability, or heavy steel which often requires on-site adjustments, LSF offers consistent quality with fewer errors during assembly.

5. Environmental Impact

LSF construction generates less on-site waste, consumes fewer natural resources, and is fully recyclable. Compared to concrete, which has a high carbon footprint, LSF is a more sustainable choice. Moreover, steel framing is compatible with high-performance insulation systems, contributing to energy-efficient buildings.

6. Cost Considerations

Although the initial material cost of LSF may be slightly higher than traditional concrete, the overall project cost is often lower due to faster construction, reduced labor, smaller foundations, and minimized waste. It also offers long-term savings in energy consumption and maintenance.

Conclusion

While each structural system has its own strengths and appropriate use cases, LSF stands out for projects requiring speed, flexibility, and high seismic resilience. It's a modern solution that aligns with current construction trends—lightweight, fast, precise, and environmentally responsible.

01

Jun 25

Key Standards and Codes in LSF (Light Steel Frame) Design

Light Steel Frame (LSF) construction is gaining global popularity due to its efficiency, lightweight nature, and versatility. However, proper structural performance and safety depend heavily on adherence to well-established design codes and standards. Here are the most important international codes that guide the design, analysis, and fabrication of LSF structures:

1. AISI Standards (North America)

The American Iron and Steel Institute (AISI) provides comprehensive guidelines for cold-formed steel design, which are widely used in the U.S. and many other countries. Key documents include:

• AISI S100: North American Specification for the Design of Cold-Formed Steel Structural Members

• AISI S240: North American Standard for Cold-Formed Steel Structural Framing

• AISI S400: Seismic Design of Cold-Formed Steel Structural Systems

These standards are often referenced in U.S. building codes and are critical for both structural and seismic design.

2. Eurocode (Europe)

In Europe, Eurocode 3 is the primary standard for steel structure design. For cold-formed steel, the relevant part is:

• EN 1993-1-3: Design of steel structures – Supplementary rules for cold-formed members and sheeting

This standard covers the calculation of load-bearing capacity, stability, and detailing for cold-formed profiles used in LSF systems.

3. AS/NZS Standards (Australia and New Zealand)

Australia and New Zealand have jointly developed a set of standards tailored to their construction environment:

• AS/NZS 4600: Cold-Formed Steel Structures

• NASH Standards: Published by the National Association of Steel-Framed Housing, these are practical guidelines specifically developed for residential and low-rise steel framing in Australia.

The AS/NZS 4600 standard is recognized internationally for its clarity and precision in cold-formed steel design.

4. BS 5950 (United Kingdom - Legacy Standard)

Although the UK has transitioned to Eurocodes, BS 5950 Part 5 was historically used for the design of cold-formed thin gauge sections. Some designers in former British territories may still refer to this standard.

5. SANS Standards (South Africa)

• SANS 10162-2: Structural Use of Steel - Part 2: Limit-State Design of Cold-Formed Steelwork

This standard is commonly used in South African engineering practice and is based on principles similar to AISI and AS/NZS standards.

Conclusion

Using the correct design code is essential for the safe and efficient performance of any LSF structure. While the core engineering principles are similar, each code has its own specific approach to design limits, safety factors, and detailing rules. Designers should always ensure they are using the standard that is recognized and approved in the region where the project is located.

Whether you are building a residential home, commercial facility, or modular structure, compliance with these standards ensures durability, safety, and long-term value.

24

May 25

Prefabricated LSF Structures: A Fast Solution for Building Schools, Clinics, and Emergency Camps

In times of urgent need—whether after natural disasters, in rapidly developing regions, or for temporary infrastructure—speed, flexibility, and durability become the top priorities in construction. Light Steel Frame (LSF) prefabricated structures offer an ideal solution for these scenarios, combining speed of assembly with high structural performance.

Why Choose LSF for Schools, Clinics, and Temporary Camps?

1. Rapid Construction

LSF components are prefabricated off-site with precision using specialized software and machinery. Once delivered to the site, the assembly process is fast, clean, and requires minimal labor. A fully functional school or clinic can often be erected in a matter of weeks instead of months.

2. Modular and Scalable Design

LSF buildings can be designed in modular units that are easy to transport, install, and expand. Whether it’s a single-classroom school or a fully equipped field hospital, the structure can grow based on evolving needs.

3. High Strength-to-Weight Ratio

Despite being lightweight, LSF systems provide excellent structural performance, even in challenging environments. They are resistant to earthquakes, wind, and corrosion—making them especially suitable for remote or disaster-prone regions.

4. Thermal and Acoustic Insulation

When combined with proper insulation materials like rock wool or PIR panels, LSF buildings offer great thermal comfort and soundproofing, essential for schools and healthcare facilities.

5. Cost-Efficient and Sustainable

The efficiency of the prefabrication process reduces waste and lowers labor costs. Moreover, steel is recyclable, and the energy consumption during production and assembly is significantly lower compared to traditional building methods.

6. Compliance with International Standards

LSF structures can be designed and manufactured according to global engineering standards (such as Eurocode or AISI), ensuring safety, reliability, and long-term performance.

Applications in Real Life

- Emergency field hospitals and clinics during health crises

- Temporary classrooms in areas with growing student populations

- Accommodation units for refugees or disaster-displaced populations

- Construction site offices and worker camps

Conclusion

Prefabricated LSF structures are not only a fast and flexible building solution but also a reliable one. With the growing demand for efficient infrastructure around the world, LSF offers a forward-thinking approach to building smarter, faster, and more responsibly.

If you're planning a school, clinic, or camp project and need a quick yet robust solution, LSF is a choice worth considering.

23

May 25

Why LSF Structures Are a Smart Choice for Villas and Second Homes

When it comes to building a villa or a second home, speed, efficiency, and long-term value matter. Light Steel Frame (LSF) construction offers a modern alternative to traditional building methods, combining durability with cost-effectiveness — making it an ideal solution for residential projects, especially in remote or scenic areas.

1. Fast Construction with Minimal Disruption

LSF systems are prefabricated and assembled with precision, significantly reducing on-site labor and construction time. This is particularly beneficial for villas or second homes built in countryside or coastal areas where accessibility may be limited.

2. Lightweight but Strong

Despite being lightweight, LSF structures are engineered to meet strict structural requirements. They offer excellent strength-to-weight ratio, making them safe and stable even in areas prone to earthquakes or strong winds.

3. Excellent Thermal and Acoustic Performance

Modern LSF systems incorporate high-performance insulation materials, ensuring thermal comfort in both hot and cold climates. They also provide good acoustic insulation — an important feature for peaceful retreats.

4. Flexible Architectural Design

LSF construction allows for creative and customizable designs. Whether you prefer a modern minimalist villa or a traditional style home, LSF adapts easily to your vision without structural limitations.

5. Eco-Friendly and Energy-Efficient

Steel is recyclable, and LSF systems generate minimal construction waste. Additionally, the energy efficiency of these homes contributes to lower utility costs and a smaller environmental footprint over time.

6. Lower Maintenance Over Time

Unlike wood or masonry, LSF structures do not suffer from issues like rot, termites, or cracking. This results in lower maintenance costs and longer lifespan — a key advantage for vacation homes that may be unoccupied for extended periods.

Conclusion:

Choosing LSF for your villa or second home means choosing a modern, sustainable, and practical building solution. It’s not just about faster construction — it's about better performance, greater design freedom, and long-term peace of mind.

20

May 25

How Much Does It Cost to Build with LSF? An Economic Comparison with Traditional Methods

When it comes to choosing a construction method, cost is always a critical factor. Light Steel Frame (LSF) construction has become increasingly popular due to its speed, precision, and efficiency—but how does it compare economically to traditional construction methods like reinforced concrete or masonry?

1. Material and Structural Cost

At first glance, the cost of steel components may appear higher than traditional materials like bricks or concrete. However, LSF systems are designed with precision, minimizing waste and excess material. Since the components are pre-engineered and manufactured with exact dimensions, there is almost no material loss on-site.

In many cases, the structural cost per m² of an LSF building is comparable or even lower than that of a conventional structure, especially when considering long-term savings.

2. Labor and Construction Time

One of the biggest advantages of LSF is the significant reduction in construction time. The pre-fabricated nature of LSF elements allows for fast assembly on-site, often reducing the overall build time by 30–50% compared to traditional methods.

This shorter timeline leads to lower labor costs, reduced site management expenses, and fewer delays due to weather or logistical challenges.

3. Foundation Savings

Because LSF structures are much lighter than concrete or brick systems, they require less massive foundations. This translates to lower excavation, concrete, and reinforcement costs—especially important in areas with poor soil conditions or seismic requirements.

4. Energy Efficiency and Operating Costs

LSF buildings typically include high-performance insulation and dry wall systems, leading to superior thermal performance. This results in lower energy bills for heating and cooling throughout the building's life cycle.

5. Maintenance and Longevity

Steel frames are resistant to termites, rot, mold, and warping, unlike wood or poorly maintained concrete. As a result, maintenance costs over time are significantly reduced, and the overall durability of the structure is improved.

6. Final Verdict: Is LSF More Affordable?

While the initial cost of materials might be slightly higher, the overall cost-efficiency of LSF construction is superior when all factors are considered—especially for fast-track projects or locations with high labor costs.

By saving on labor, foundation work, energy consumption, and long-term maintenance, LSF often proves to be the smarter financial choice.